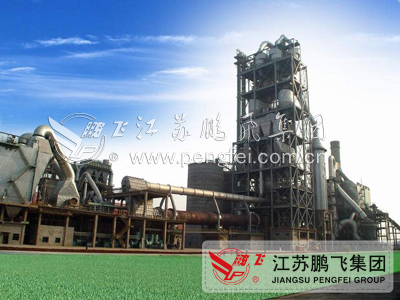

A cement production line is a construction project consisting of a series of supporting equipment for producing cement. It mainly consists of crushing equipment, homogenization equipment, raw material preparation equipment, drying equipment, preheating and decomposition equipment, clinker burning equipment, cooling equipment, grinding equipment, packaging equipment, conveying equipment, environmental dust collection equipment, etc. Jiangsu Pengfei Group provides process design, civil construction, complete equipment, installation and commissioning, technical services, and engineering general contracting for cement production lines. A cement production line is a construction project consisting of a series of supporting equipment for producing cement. It mainly consists of crushing equipment, homogenization equipment, raw material preparation equipment, drying equipment, preheating and decomposition equipment, clinker burning equipment, cooling equipment, grinding equipment, packaging equipment, conveying equipment, environmental dust collection equipment, etc. Jiangsu Pengfei Group provides process design, civil construction, complete equipment, installation and commissioning, technical services, and engineering general contracting for cement production lines. A cement production line is a construction project consisting of a series of supporting equipment for producing cement. It mainly consists of crushing equipment, homogenization equipment, raw material preparation equipment, drying equipment, preheating and decomposition equipment, clinker burning equipment, cooling equipment, grinding equipment, packaging equipment, conveying equipment, environmental dust collection equipment, etc. Jiangsu Pengfei Group provides process design, civil construction, complete equipment, installation and commissioning, technical services, and engineering general contracting for cement production lines.

Process parameters

In the process of cement production line, for every 1 ton of Portland cement produced, 3 tons of materials (including various raw materials, fuels, clinker, mixtures, and gypsum) need to be ground. According to statistics, the power consumption of the dry cement production line grinding operation accounts for more than 60% of the total power consumption of the plant, of which raw material grinding accounts for more than 30%, coal grinding accounts for about 3%, and cement grinding accounts for about 40%. Therefore, reasonable selection of grinding equipment and process flow, optimization of process parameters, correct operation, and control of operating systems are of great significance for ensuring product quality and reducing energy consumption.

Production method

Cement production mainly uses limestone and clay as raw materials, which are crushed, proportioned, and vertically ground into raw materials. Then, they are fed into a cement rotary kiln to calcine the mature materials. The clinker is added with an appropriate amount of gypsum, mixed with some mixed materials or additives, and ground into cement by a roller press and cement mill. Finally, it is transported out of the factory by a packaging machine or bulk machine. Cement production equipment can be divided into two types: dry cement production lines and wet cement production lines, depending on the method of raw material preparation. (1) Dry process cement production process flow. The method of simultaneously drying and grinding raw materials, or first drying and grinding them into raw material powder, and then feeding them into a dry rotary kiln for calcination into clinker. There is also a method of adding an appropriate amount of water to the raw material powder to make raw material balls, which are then sent to the Libol kiln for calcination into clinker, called semi dry method, which is still one of the dry production methods. The main advantage of dry production is low heat consumption. The heat consumption of clinker in dry kilns with preheaters is 3140-3768 coke/kg. The disadvantage is that the raw material composition is not easily uniform, the workshop has high dust emissions, and the power consumption is high. (2) Wet cement production process flow. The method of grinding raw materials into slurry by adding water powder and feeding them into a wet rotary kiln to calcine mature materials. There is also a method of dehydrating the raw material slurry prepared by wet method and making raw material blocks into kiln calcined mature materials, called semi wet method, which is still one of the wet production methods. Wet production has the advantages of simple operation, easy control of raw material composition, good product quality, convenient slurry transportation, and less dust in the workshop. The disadvantage is high heat consumption, with clinker heat consumption usually ranging from 5234 to 6490 coke/kg.

The device includes

The main equipment of the cement production line includes: cement rotary kiln, cyclone preheater, cooler, crusher, vertical mill, roller press, cement mill, coal mill, dryer, dust collector, packaging machine, bulk loader, conveyor, electrical control, etc.

Process flow

1) Limestone crushing, transportation, and storage. Limestone crushing is carried out using an MB56/75 crusher. When the maximum size of the feed ore is ≤ 1500mm and the particle size of the discharge is ≤ 75mm, the crushing capacity of the crusher is 500-600t/h; The limestone from the crusher is transported by a belt conveyor to a circular limestone pre homogenization yard (with a storage capacity of 34100 tons) with a diameter of 80m for pre homogenization and storage. The stacker (with a stacking capacity of 800t/h) uses cantilever and loop continuous feeding, while the reclaimer (with a stacking capacity of 500t/h) uses bridge and end face feeding and central unloading. The homogenized limestone is transported to the raw material batching station by a belt conveyor.

2) Auxiliary raw material storage, crushing, and transportation. The auxiliary raw materials sandstone and iron ore are transported into the factory by truck and unloaded into an open-air storage yard for storage. Among them, the sandstone open-air storage yard has a specification of 60 m × 20 m and a storage capacity of 5100 tons; The open-pit iron ore yard is 32m × 20m with a storage capacity of 2730 tons. A PC1609 hammer crusher is used for both sandstone and iron ore. When the feed particle size is ≤ 600mm and the discharge particle size is ≤ 25mm, the crushing capacity is 50-70t/h; The crushed sandstone and iron ore are transported by belt conveyors to their respective batching warehouses at the raw material batching station for storage. The auxiliary raw material fly ash is transported into the factory by bulk trucks and sent to the raw material batching station's fly ash batching warehouse for storage through a pipeline using a self dumping system.

3) Raw material batching station. The raw material batching station is equipped with four batching warehouses for limestone, sandstone, iron ore, and fly ash (all with a specification of φ 12 m × 25m and a storage capacity of 2200.1600. 2200.770 tons respectively). Weighing feeders are installed at the bottom of each warehouse to quantitatively provide various materials according to the set ratio. The raw materials are transported by a belt conveyor to the vertical grinding system for grinding.

4) Raw material grinding and waste gas treatment. The raw material grinding adopts MLS3626 vertical mill, and its drying heat source is the exhaust gas from the preheater. When the particle size of the raw material entering the mill is 90% ≤ 75mm, the product fineness is 80 μ m square hole sieve residue<12%, the moisture content of the raw material entering the mill is<8%, and the moisture content of the raw material exiting the mill is<1%, the system production capacity is 185t/h (after wear). After being separated by a fine powder separator, the raw materials are mixed with dust collected by a humidification tower and an electrostatic precipitator. They are then transported to the raw material homogenization silo for homogenization and storage via a chute and bucket elevator; The exhaust gas from the grinding process is purified and treated by an electrostatic precipitator before being discharged into the atmosphere.

5) Raw material homogenization silo and raw material feeding kiln. The qualified raw materials from the grinding process are distributed through multiple points by the raw material distributor on the top of the warehouse and enter the raw material homogenization warehouse with a diameter of 18m × 50m CP type (effective storage capacity of 9000t) for homogenization. Then, they are quantitatively discharged into the kiln system through the discharge device. The raw material feeding system is equipped with a load bin, under which there are metering and flow control devices. The metered raw materials are fed into the kiln tail preheater system by equipment such as bucket elevators.

6) Clinker burning system and storage. The clinker burning system consists of a low-pressure loss single series online five stage preheater and a decomposition furnace (RF5/2500 type, with a kiln decomposition rate greater than 90%), as well as a new type of control flow grate cooler with a diameter of 4.0 × 60m and LBT32216. Among them: ① The clinker from the kiln is cooled by a grate cooler and then transported by a chain bucket conveyor and a disc conveyor to a 2- φ 18 × 40m circular warehouse (with an effective storage capacity of 2-10000 tons) for storage. The clinker from the kiln is sent to the cement clinker external transportation and cement batching station through an unloading device and a belt conveyor. ② The high-temperature gas at the hot end of the cooling machine is introduced into the decomposition furnace through a tertiary air duct as the combustion gas for the decomposition furnace, while the hot gas at the medium temperature end is introduced into the coal mill as the drying heat source for the raw coal; The exhaust gas discharged from the tail end is purified by an electrostatic precipitator and discharged into the atmosphere through a chimney, with a dust concentration (converted to standard conditions) of less than 100mg/m3

7) Raw coal storage and transportation, coal powder preparation and transportation. The raw coal transported by car into the factory is stored and pre homogenized in a 21m × 113m crane garage (with a storage capacity of 9300t). There are two raw coal bunkers in the crane yard. On the one hand, it is to shorten the walking distance of the crane, and on the other hand, it is to consider the combination of two types of coal with different qualities. There is a weighing feeder at the bottom of the bunker, and after measurement, the coal is sent to the coal mill for grinding by a belt conveyor. A MPF1713 roller disc coal mill is used for coal powder preparation, arranged outdoors. When the moisture content of the coal powder is ≤ 10%, the moisture content of the coal powder is ≤ 1%; When the particle size of raw coal is ≤ 50mm and the fineness of coal powder is 80 μ m with a sieve residue of 11%, the system output is 20t/h. The ground coal powder enters the sorting machine with the airflow for sorting. The finished coal powder is brought into the pulse bag dust collector of the air box by the airflow for collection and then sent to two coal powder silos for storage by the screw conveyor. The exhaust gas is purified and discharged into the atmosphere. The bottom of the coal powder silo is equipped with a coal powder metering system, which measures the coal powder and sends it to the kiln head and the decomposition furnace for combustion.

8) Slag drying and conveying, gypsum crushing and conveying. As a mixed material, slag is transported into the factory by truck and unloaded into an open-air storage yard for storage. The slag is then sent to a bucket elevator by a shovel and sent to a drying machine with a diameter of 2.4 × 18.350m for drying. The drying capacity is ≥ 30t/h (initial moisture content of the material is 20%, final moisture content is 1.5%). Gypsum is transported into the factory by truck and unloaded into an open-air storage yard with a capacity of 4000 tons. It is then fed into the PFC-1609 impact hammer crusher (with a production capacity of 50-70t/h when the feed particle size is ≤ 600mm and the discharge particle size is ≤ 25mm) by a heavy-duty plate feeder for crushing. The crushed gypsum is transported to the gypsum batching bin for storage by a bucket elevator and a belt conveyor.

9) Cement grinding, transportation, and storage. The cement batching station has four batching warehouses for clinker, gypsum, limestone, and slag, among which the clinker warehouse has a diameter of 10 m × 22 m and a storage capacity of 2000 tons; The gypsum silo, slag silo, and limestone silo are all of diameter 8 m × 22 m, with reserves of 800. 400. and 900 tons, respectively. Each warehouse is equipped with a weighing feeder at the bottom, which quantifies various materials according to the set ratio. There is also a clinker bulk facility on the storage side of the clinker batching warehouse for external use of clinker. After the four materials are proportionally discharged by the feeding metering equipment, they are transported by a belt conveyor to two sets of circular flow cement grinding systems consisting of a Φ 3.8 × 13m ball mill and an efficient powder selector for grinding. When the specific surface area of cement is 3200-3400cm2/g, the production capacity of a single system is 75t/h; The ground material is sent to the high-efficiency powder sorting machine for sorting by the bucket elevator, and the coarse powder is further ground by the return mill. The cement finished product is collected by the pneumatic pulse bag dust collector and then sent to 8 cement warehouses (with a single storage capacity of 5300t) with a diameter of 15 m × 34m by the air conveying chute and bucket elevator for storage. The exhaust gas from the cement grinding system enters the high-efficiency gas box pulse bag filter for purification before being discharged into the atmosphere. After the outbound cement is unloaded by the bottom unloading device, it is transported to the cement packaging workshop and cement bulk warehouse by belt conveyor, bucket elevator, and air conveyor chute. Two eight nozzle rotary packaging machines are used for cement packaging, each with a capacity of 90t/h. The packaged bagged cement is sent to the 84m × 30m bagged cement finished product warehouse for storage (with a storage capacity of 6000t) through the unloading and conveying system, or can be directly loaded and shipped. There are two cement truck bulk facilities under the cement bulk warehouse for truck bulk use.

Real time updates on cutting-edge information, presenting Pengfei and industry trends in a timely, comprehensive, and intuitive manner.

Real time updates on cutting-edge information, presenting Pengfei and industry trends in a timely, comprehensive, and intuitive manner.

We firmly believe that talent is the foundation of enterprise development. We adhere to the talent concept of "people-oriented, co creation and win-win", respect the personality and creativity of each employee, and are committed to providing employees with broad development space and a fair competitive platform.

We firmly believe that talent is the foundation of enterprise development. We adhere to the talent concept of "people-oriented, co creation and win-win", respect the personality and creativity of each employee, and are committed to providing employees with broad development space and a fair competitive platform.

中文

中文 English

English